The latest technology for manual wire stripping on wire harness production tables is the Sylade 7H handheld laser stripper. It is compact, lightweight and portable!

High precision semiconductor lasers circle the cable and cut the outer jacket with high accuracy in depth and width. Sylade 7H can handle a wide variety of cables. This handy device is easy to use and can replace conventional tools.

TECHNICAL DATA

- Wire diameter range OD: 1-7 mm (AWG 6-26)

- Maximum stripping length: 200 mm (8 in.)

- Cycle start: trigger activated laser

- Laser cut: circular

- Insulation material: PTFE, polyimide, ETFE, X-ETFE, FEP, etc.

- Interface: 3.5″ screen, USB, RJ45.

- Ambient temperature: +15°C to +35°C (59°F to 95°F)

- Humidity: <85%, non-condensing

- Noise level: <65 Db

- Device weight: 1.75 kg (3.9 lbs)

- 4 m (13 ft) control cable

- Electrical connection: 100-230 VAC / 50-60 Hz

- Power consumption: <200W

- Class 1 laser: can be used in open workshops

- Compliance: CE, FDA, FCC

- Standard: EN2812, SAE AIR6894

DIE SYLADE 7 H-LINIE

- Sylade 7b H (blau – 445 nm)

- Sylade 7v H (violett – 405 nm)

WHY LASER STRIPPING?

Over the last two decades, the aerospace industry has seen a huge upsurge in laser processing solutions (cutting, welding, marking, etc.).

The production of electrical harnesses is a booming sector, driven by the strong growth of aircraft production and the race for autonomous cars (multiplication of sensors and multimedia systems, complexity of harnesses). The use of high-precision laser solutions for marking or stripping lighter, technical and sensitive electrical cables is constantly increasing.

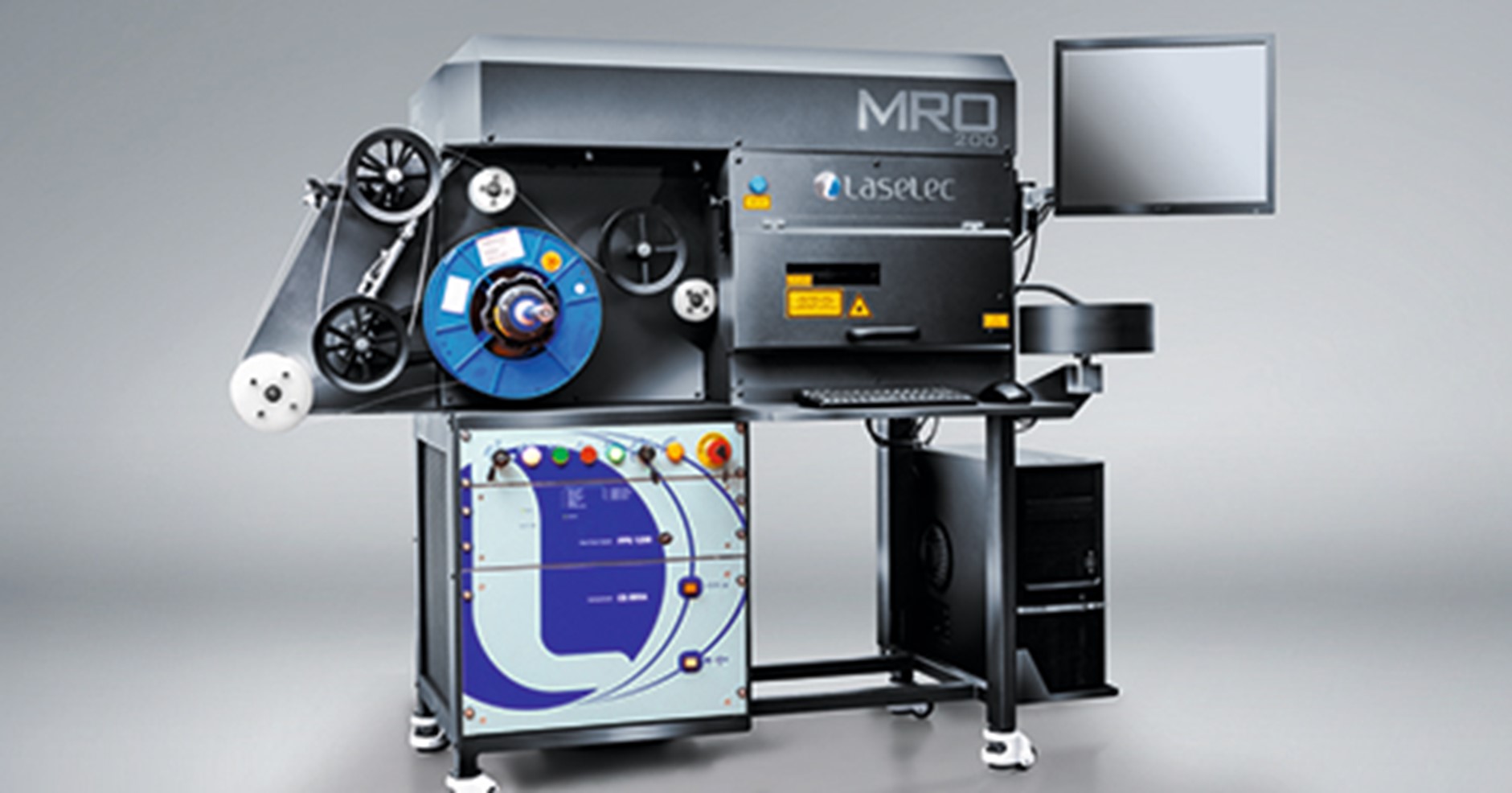

In recent years, laser cable stripping machines have followed a trend of refinement, increasing in power, size and capacity to address new markets in the industry. Laselec has chosen to work against the tide by relying on innovation, miniaturization, ergonomics and ease of use. Laselec has developed Sylade, a patented technology for contactless cable stripping based on laser diodes. Used in aerospace cabling applications, Sylade technology offers a level of precision, quality and consistency far superior to conventional tools. Laser stripping is establishing itself as the best solution for stripping shielded, twisted and multicore cables, meeting the new requirements of the aerospace standards ASD EN2812 and SAE AIR6894, updated and published in recent months.