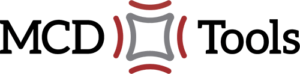

UV laser marking of cables is now affordable and available for everyone, thanks to the efficient and compact machines of the MRO 200 series.

Thanks to the close collaboration with customers and the knowledge of their needs, LASELEC has developed a laser marking series for small to medium production runs and for single orders: the MRO 200.

The MRO 200 series is the ideal complement to the ULYS Modena line (medium to very large production) and meets the needs of aircraft maintenance, repair and overhaul centers to ensure maximum ROI. It can also be used as a post-processing machine alongside ULYS Modena machines in a production environment. Finally, it is perfect for various production shops with modest output that want to use a safe, efficient and innovative marking method.

This machine is ideal for users who want to control their production costs. The very competitive price is not the only advantage of this machine; our customers also appreciate its ease of use and high-quality construction. A number of features of this machine can also be found on the ULYS Modena machine.

MODEL RANGE

The MRO 200 range includes 4 models to meet your production requirements:

- MRO 200-A: This is LASELEC's entry-level model that features remarkable productivity and does not compromise on quality.

- MRO 200-B: The MRO 200-B has all the features of the MRO 200 line.

- MRO 200-X: The MRO 200-X is the best-selling model in the MRO 200 line and can handle high production volume.

- MRO 200-XS: This is the most productive machine of the MRO 200 line with a very interesting price-performance ratio.

ADVANTAGES

The MRO 200-A is characterized by:

- A highly competitive price with the best productivity/price ratio on the market.

- Low operating costs; no daily consumables.

- Low maintenance, as no daily maintenance is required, and high reliability.

- User-friendly controls and automatic control systems.

- Remote maintenance kit for remote diagnosis and maintenance.

- Compact and ergonomic design.

- A solid and reliable cable handling and cutting system that guarantees the integrity of the cable insulation.

- Easy and fast coil change.

- An extremely stable and powerful laser marker.

- An innovative and safe technology.

SPECIFICATIONS

- Designed for low to medium production requirements, maintenance, repair and overhaul.

- 355 nm frequency tripled Nd-YAG solid state laser - Class 1.

- Produces a durable, high-contrast marking that can't be beat. Suitable for all UV-markable single-core cables and jacketed multi-core cables.

- Can handle cable lengths from 6 inches to 3,277 feet (15 cm to 999 m).

- Auto-calibration and self-alignment of the laser.

- Real-time energy control (for contrast) with automatic adjustment to desired specifications.

- Data acquisition by manual input, USB stick, hard drive or plant network.

- Automatic wire tensioning and cutting system that meets aerospace industry standards.

- System control via IBM compatible PC with WINDOWS 7.

- User-friendly EasyProd MRO multilingual software.

- Compact, ergonomic structure mounted on casters.

- User protection hood that complies with laser safety regulations.

QUALIFICATIONS

The MRO 200 marking machines have been approved and qualified by BOEING in accordance with BAC 5152 and by AIRBUS in accordance with AIPS, and comply with international aviation standards such as SAE ARP5607. They have also been qualified and approved by major aircraft manufacturers and are used in civil and military programs worldwide, including:

- AGUSTA-WESTLAND

- AIRBUS

- ATR

- BELL-HUBSCHRAUBER

- BOEING

- BOMBARDIER / LEARJET

- DASSAULT

- ECLIPSE

- EMBRAER

- EUROCOPTER

- GULFSTREAM AEROSPACE

- HAL

- LOCKHEED MARTIN

- MIG

- RAYTHEON

- SIKORSKY

- T.A.I.

- etc...

CUSTOMER VOICES

BCAircraft :

"Thanks to the MRO 200, we have eliminated manual cutting and sleeves. We cut and mark the cables directly with the laser. We have increased our productivity by 25%."

Aquitaine Electronique :

" We purchased an MRO 200-A laser marker for cables in 2014. Since then, we have stopped using heat shrink tubing, automatic cutting and cable marking. We have seen a significant reduction in our operating costs and production hours. The marking is done directly on the insulation and is clear, legible and permanent.

Our employees have easily adapted to the LASELEC machine. Our investment has paid off with the increase in productivity (+18%) and the elimination of the heat shrink process."